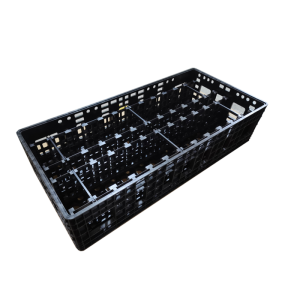

Plastic Battery Tray For Punch Cells

Features

1. Easy transportation: Plastic battery trays are lightweight, strong, and portable, making them ideal for both short- and long-distance travel.

2. Battery protection: The plastic battery tray may secure the battery to prevent damage from collision or tilt during transit and shield it from contact with wet and corrosive materials.

3. Boost productivity: A plastic battery tray can arrange and stack batteries neatly, maximizing storage capacity and facilitating easy pick-up and management.

Application scenario

1. Battery producers: Batteries need to be sorted, stored, and transported during the manufacturing process. Plastic battery trays are a good option for protecting batteries because they increase output efficiency and cut down on waste.

2. Battery merchants: Battery dealers are responsible for sorting, storing, displaying, and selling batteries of various models and specifications. The plastic battery tray can neatly stack and arrange batteries, making it simple to store and transport items while also guaranteeing battery quality.

3. Logistics firm: When transporting batteries, it's important to assure their safety and that they won't be harmed, as well as to boost productivity and cut costs. The light, sturdy, and long-lasting qualities of the plastic battery tray make it an efficient aid in the transit of supplies.

In summary, plastic battery trays are widely utilized in the logistics and battery industries as effective, sustainable, and durable battery storage and transportation tools.

Our Factory

Our Company

Lingying Technology were founded in 2017.Expand to be two factories in 2021,In 2022,was nominated as a high-tech enterprise by the government, basic on more than 20 invention patents.More than 100 production equipments,factory area more than 5000 square meters."To establish a career with precision and win with quality" is our eternal pursuit.

Certificates

Delivery

List of customer purchasing concerns

1.What are the differences of your products in the industry?

We can offer many kinds of trays ,including plastic trays,restrained trays and customize the relevant equipment which will be used in the battery production line

2.How long does your mold normally last? How to maintain daily? What is the capacity of each mold?

The mold is normally used for 6~8 years, and there is a special person responsible for daily maintenance. The production capacity of each mold is 300K~500KPCS

3. How long does it take for your company to make samples and open molds? 3. How long does your company's bulk delivery time take?

It will take 55~60 days for mold making and sample making, and 20~30 days for mass production after sample confirmation.

4. What is the total capacity of your company? How large is your company? What is the annual value of production?

It is 150K plastic pallets per year, 30K restrained pallets per year, we have 60 employees, more than 5,000 square meters of plant, On the year of 2022 ,annual output value is USD155 millions

5.What testing equipment does your company have?

Customizes the gauge according to the product,outside micrometers,inside micrometers and so on.

6. What is your company's quality process?

We will test the sample after opening the mold, and then repair the mold until the sample is confirmed. Large goods are produced in small batches first, and then in large quantities after stability.