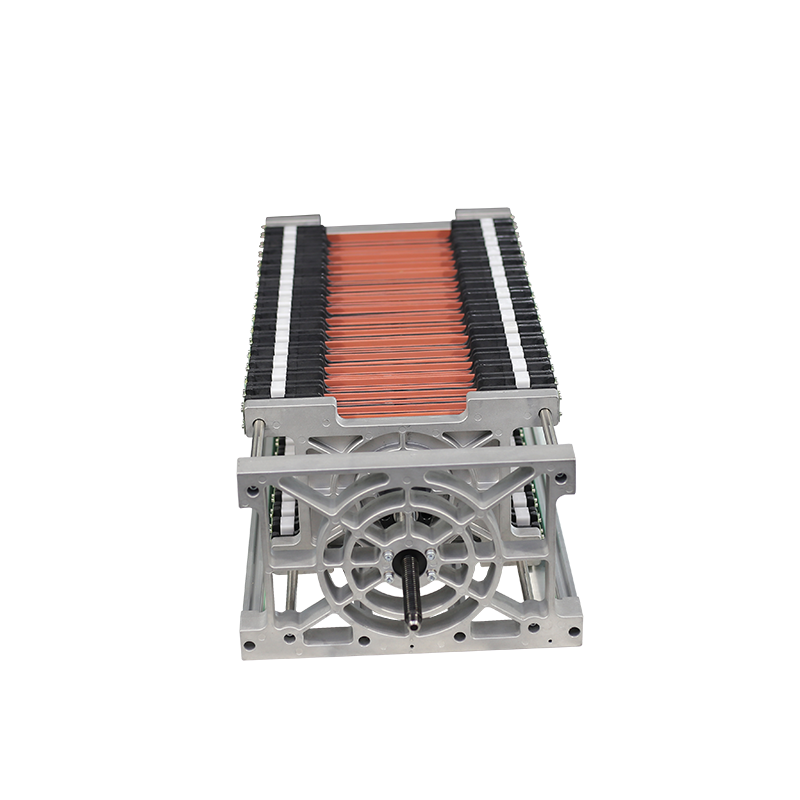

Restraint Battery Tray With Silica Gel Covered

The restraint battery tray is designed for loading and transporting inflammable and explosive materials such as batteries.

Main Application

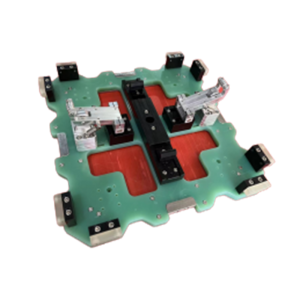

The trays are designed to meet the specific dimensions required for prismatic cells, ensuring maximum efficiency and effectiveness of the production line.

With a durable construction designed to withstand the wear and tear of busy production facilities, the Restraint Battery Tray is ideal for businesses looking for reliable, durable trays. The non-slip surface of the tray helps keep the prismatic batteries secure during the forming process, minimizing the risk of damage or loss.

What sets the Restraint Battery Tray apart is its versatility and flexibility. The tray can be used with a variety of prismatic battery models, making it an invaluable addition to any production line, no matter what type of battery you are using. Plus, the stackable design of the trays allows for easy storage and transport, helping to save space and streamline your workflow.

Its lightweight construction and easy-to-clean surface make it quick and easy to use, allowing you to focus on what matters most – producing high-quality prismatic batteries that meet your customers' expectations.

Main Feature

This innovative tray is designed with many features that make it the perfect choice for those looking to simplify their equipment process and save on equipment costs.

One of the outstanding features of the Restraint Battery Tray is its ability to compress batteries, allowing you to store more batteries in less space. This means you can store more batteries in the same space, which will help save on storage costs.

The constraining battery tray is designed to simplify equipment flow. This means you can quickly and easily replace the battery in your device without spending hours figuring out how all the parts fit together.

Fast implementation of battery model replacement is another key feature of Restraint Battery Tray. Thanks to its innovative design, you can quickly and easily change the batteries in the battery without dismantling the entire device setup.

Our Factory

Our Company

Lingying Technology were founded in 2017.Expand to be two factories in 2021,In 2022,was nominated as a high-tech enterprise by the government, basic on more than 20 invention patents.More than 100 production equipments,factory area more than 5000 square meters."To establish a career with precision and win with quality" is our eternal pursuit.

Certificates

Delivery

List of customer purchasing concerns

1.What are the differences of your products in the industry?

We can offer many kinds of trays ,including plastic trays,restrained trays and customize the relevant equipment which will be used in the battery production line

2.How long does your mold normally last? How to maintain daily? What is the capacity of each mold?

The mold is normally used for 6~8 years, and there is a special person responsible for daily maintenance. The production capacity of each mold is 300K~500KPCS

3. How long does it take for your company to make samples and open molds? 3. How long does your company's bulk delivery time take?

It will take 55~60 days for mold making and sample making, and 20~30 days for mass production after sample confirmation.

4. What is your company's quality process?

We will test the sample after opening the mold, and then repair the mold until the sample is confirmed. Large goods are produced in small batches first, and then in large quantities after stability.

5. What are the specific categories of your products?

Plastic pallets, restrained pallets, related equipment, gauge, etc.

6. What are the acceptable payment methods for your company?

30% down payment, 70% before delivery.

7.Which countries and regions have your products been exported to?

Japan, UK, USA, Spain and so on.

8.How do you keep guests' information confidential?

The molds customized by customers are not open to the public.

9. Corporate sustainability initiatives?

We often carry out team building activities, training and so on. And timely solve the staff and family ‘s life issues