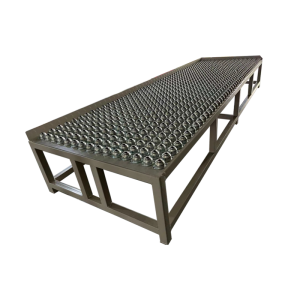

Round hat tray material rack

Application

Used for new energy pallet transfer

Advantage

Can be modified according to customer product drawing design processing.

Product Description

Our customizable material racks are designed specifically for transporting new energy pallets, providing a versatile solution that can be customized to meet specific customer requirements. The rack features anti-static rubber and custom paint, providing a reliable and adaptable option for pallet transportation in the new energy industry.

Product Application

Material racks are mainly used for the transfer of new energy pallets, providing flexible and customizable solutions for material transportation in the industry. Its design allows for easy modification to customer product designs, ensuring a seamless fit for a variety of pallet types.

Product Advantages

Customizable designs: Racks can be modified to match customers’ product designs, providing customized solutions for specific pallet shipping needs.

Anti-static performance: The frame is made of anti-static rubber, which provides anti-static protection and ensures the safe transportation of sensitive electronic components.

Paint Customization: Paint customization options allow racks to be customized to match specific color schemes or brand requirements.

Product Features

Versatile Adaptability: The design of the rack can be easily modified to accommodate different pallet types, making it a versatile solution for a variety of transportation needs.

Anti-static rubber: The addition of anti-static rubber ensures the safe transportation of new energy pallets and protects sensitive components from electrostatic discharge.

Custom paint options: The ability to customize the paint surface provides a personalized touch and allows racks to be aligned with a specific brand or color preference.

In summary, our customizable material racks provide a flexible and adaptable solution for the transportation of new energy pallets. Featuring customizable designs, anti-static properties and paint options, the racks are designed to meet the specific needs of the new energy industry, providing a reliable, customized solution for pallet shipping.

Our Company

Lingying Technology were founded in 2017.Expand to be two factories in 2021,In 2022,was nominated as a high-tech enterprise by the government, basic on more than 20 invention patents.More than 100 production equipments,factory area more than 5000 square meters."To establish a career with precision and win with quality" is our eternal pursuit.

Certificates

Delivery

List of customer purchasing concerns

1.What are the differences of your products in the industry?

We can offer many kinds of trays ,including plastic trays,restrained trays and customize the relevant equipment which will be used in the battery production line

2.How long does your mold normally last? How to maintain daily? What is the capacity of each mold?

The mold is normally used for 6~8 years, and there is a special person responsible for daily maintenance. The production capacity of each mold is 300K~500KPCS

3. How long does it take for your company to make samples and open molds? 3. How long does your company's bulk delivery time take?

It will take 55~60 days for mold making and sample making, and 20~30 days for mass production after sample confirmation.

4. What is the total capacity of your company? How large is your company? What is the annual value of production?

It is 150K plastic pallets per year, 30K restrained pallets per year, we have 60 employees, more than 5,000 square meters of plant, On the year of 2022 ,annual output value is USD155 millions

5.What testing equipment does your company have?

Customizes the gauge according to the product,outside micrometers,inside micrometers and so on.

6. What is your company's quality process?

We will test the sample after opening the mold, and then repair the mold until the sample is confirmed. Large goods are produced in small batches first, and then in large quantities after stability.