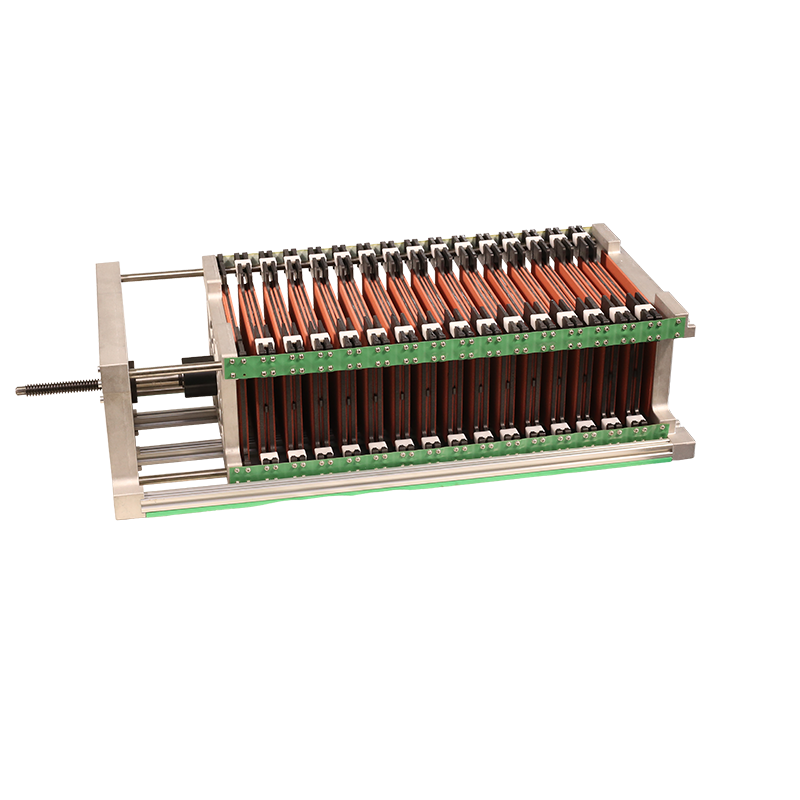

Soft Packing Battery Pressurized Tray

Main Application

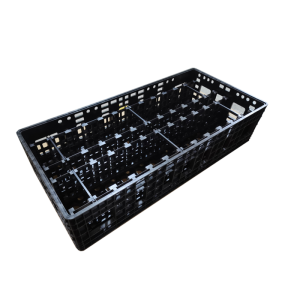

This tray is designed for storage of pouch cells during the formation and part-volume processes of battery production. The tray is made to perfectly fit the dimensions of the pouch battery, ensuring that the battery remains safe and stable when stored.

The Soft Pack Battery Pressurization Tray is a durable, quality product. Crafted from durable materials and precision engineered, this tray is the perfect addition to any battery line. Its pressurized design ensures the battery remains sealed and protected, providing an extra layer of safety during storage.

In addition to its practical application in battery production, flexible battery pressurized trays are also very easy to use. Its lightweight and compact design means it can be moved and transported with ease, making it ideal for anyone who needs to store pouch batteries in different locations.

With its high quality design, ease of use and durability, this tray is perfect for any battery production application.

Main Feature

Our flexible pack battery pressurized trays are the perfect solution for your power needs. It is designed to simplify your manufacturing process and help you save on equipment costs. By compressing the battery, we minimize the space taken up by the tray and the weight of the battery while increasing its power capacity.

Our pressurized trays are equipped with an easy-to-use mechanism to help you replace battery models efficiently. Replacing battery models in our Soft Pack Battery Pressurized Trays is a quick and easy process that ensures your equipment downtime is kept to a minimum.

Our soft pack battery pressurized trays are made from high quality materials to ensure durability and long-lasting performance. With our trays, you can rest assured that you are getting a quality product that will provide you with years of reliable service.

Flexible Packaging Battery Pressurized Trays are in high demand across various industries. It is ideal for use in electric vehicles, electric bicycles, and many other types of portable electronic devices. Quickly realize the battery change mode, no longer have to worry about running out of power.

Our pouch battery pressurized tray is the perfect solution to simplify your equipment process, save equipment cost, and realize fast battery cell mold change.

List of customer purchasing concerns

1.What are the differences of your products in the industry?

We can offer many kinds of trays ,including plastic trays,restrained trays and customize the relevant equipment which will be used in the battery production line

2.How long does your mold normally last? How to maintain daily? What is the capacity of each mold?

The mold is normally used for 6~8 years, and there is a special person responsible for daily maintenance. The production capacity of each mold is 300K~500KPCS

3. How long does it take for your company to make samples and open molds? 3. How long does your company's bulk delivery time take?

It will take 55~60 days for mold making and sample making, and 20~30 days for mass production after sample confirmation.

4. What is the total capacity of your company? How large is your company? What is the annual value of production?

It is 150K plastic pallets per year, 30K restrained pallets per year, we have 60 employees, more than 5,000 square meters of plant, On the year of 2022 ,annual output value is USD155 millions

5.What testing equipment does your company have?

Customizes the gauge according to the product,outside micrometers,inside micrometers and so on.

6. What is your company's quality process?

We will test the sample after opening the mold, and then repair the mold until the sample is confirmed. Large goods are produced in small batches first, and then in large quantities after stability.

Our Factory

Our Company

Lingying Technology were founded in 2017.Expand to be two factories in 2021,In 2022,was nominated as a high-tech enterprise by the government, basic on more than 20 invention patents.More than 100 production equipments,factory area more than 5000 square meters."To establish a career with precision and win with quality" is our eternal pursuit.

Certificates

Delivery