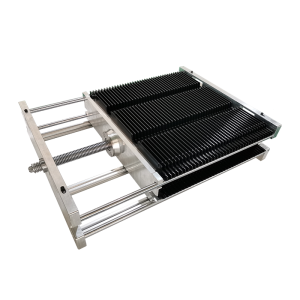

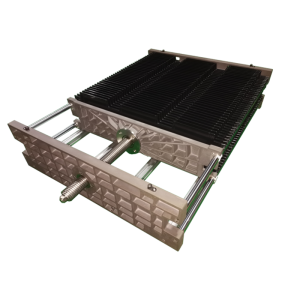

Square cell pressure tray

Application

The battery tray is the main transfer vehicle of the battery cell in the test section, which is mainly responsible for the transfer, static and reinspection of the battery cell manufacturing process.

Advantage

All-round protection of the cell,compatible with universal, fast realization the cell model replacement

Product Description

Our innovative plastic tray is designed specifically for the storage and handling of prismatic cell battery confinement, providing a streamlined solution for battery manufacturers. With a focus on compressing batteries, simplifying equipment processes, and reducing costs, our tray offers a versatile and efficient option for accommodating various battery models.

Product Application

The plastic tray is tailored for the storage and handling of prismatic cell battery confinement, commonly used in a range of electronic devices. It is ideal for battery manufacturers and assembly plants seeking a reliable and cost-effective solution for managing their battery inventory. The tray’s adaptable design allows for seamless integration into existing production lines, making it a valuable asset for companies in the battery industry.

Product Advantages

Streamlined Battery Compression: Our tray is engineered to efficiently compress prismatic cell batteries, optimizing storage space and facilitating easy handling during production processes.

Simplified Equipment Workflow: By providing a standardized platform for battery storage, our tray simplifies equipment processes, reducing the need for custom fixtures and streamlining production workflows.

Cost Savings: The innovative design of our tray helps to minimize equipment costs by eliminating the need for specialized storage solutions, ultimately contributing to overall cost savings for battery manufacturers.

Rapid Battery Model Replacement: With its flexible and adaptable structure, our tray enables quick and easy replacement of battery models, allowing for seamless transitions between different product lines.

Product Features

Durable Construction: The plastic tray is constructed from high-quality, durable materials, ensuring long-term reliability and performance in demanding production environments.

Customizable Options: We offer customizable options to accommodate specific battery dimensions and production requirements, providing tailored solutions for diverse manufacturing needs.

Compatibility: Our tray is compatible with a wide range of prismatic cell battery confinement, making it a versatile and practical choice for battery manufacturers operating in various sectors.

In conclusion, our innovative plastic tray offers a comprehensive solution for efficient battery storage and handling, addressing the specific needs of battery manufacturers in the global market. With its focus on compression, workflow simplification, cost savings, and adaptability, our tray is poised to enhance the productivity and efficiency of battery production processes worldwide.

Our Company

Lingying Technology were founded in 2017.Expand to be two factories in 2021,In 2022,was nominated as a high-tech enterprise by the government, basic on more than 20 invention patents.More than 100 production equipments,factory area more than 5000 square meters."To establish a career with precision and win with quality" is our eternal pursuit.

Certificates

Delivery

List of customer purchasing concerns

1.What are the differences of your products in the industry?

We can offer many kinds of trays ,including plastic trays,restrained trays and customize the relevant equipment which will be used in the battery production line

2.How long does your mold normally last? How to maintain daily? What is the capacity of each mold?

The mold is normally used for 6~8 years, and there is a special person responsible for daily maintenance. The production capacity of each mold is 300K~500KPCS

3. How long does it take for your company to make samples and open molds? 3. How long does your company's bulk delivery time take?

It will take 55~60 days for mold making and sample making, and 20~30 days for mass production after sample confirmation.

4. What is the total capacity of your company? How large is your company? What is the annual value of production?

It is 150K plastic pallets per year, 30K restrained pallets per year, we have 60 employees, more than 5,000 square meters of plant, On the year of 2022 ,annual output value is USD155 millions

5.What testing equipment does your company have?

Customizes the gauge according to the product,outside micrometers,inside micrometers and so on.

6. What is your company's quality process?

We will test the sample after opening the mold, and then repair the mold until the sample is confirmed. Large goods are produced in small batches first, and then in large quantities after stability.